The new ErP EcoDesign directive

Targets of the EU

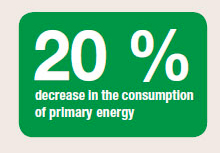

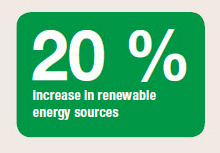

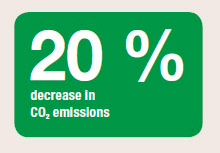

The European Union has set high targets regarding the climate protection which are to be archieved by 2020. They are defined by the term ’20-20-20 targets’ which include a 20% cut in green house gas emissions by 2020, a 20% increase in use of renewable by 2020 and a 20% vut in Energy consumption through improbe Energy efficiency by 2020.

The European Union has set itself these ambitious objectives

On 01 January 2013, the 206/2012 regulations (EU) come into force and will be the transposition of the conditions established in the ErP 2009/125 CE Directive for domestic use air-conditioners with cooling capacity up to 12 kW, in order to promote an eco-compatible design of products that use energy and to reduce CO2 emissions and energy consumption by 20% by 2020 through the application of very high energy efficiency standards.

The reason for which today the ErP directive also includes air-conditioning systems is obvious: air-conditioning technology has become part of our daily life. In the summer, almost no-one is willing to forgo the comfort of an air-conditioning system in their car and an increasing number of families and home owners install air-conditioning systems.

In this field, the technical developments of recent years have been very effective with regard to energy efficiency, in particular if we take into consideration the brands of very well known producers such as Mitsubishi Electric.

CE Certification

The ErP Directive aims to encourage the design of high energy efficient products through appropriate policy instruments.

The framework directive defines the groups of products affected and the framework conditions applicable.

The products that consume energy are affected by the directive if they meet the following criteria:

- volume of annual sales within the EU of at least 200,000 pieces;

- significant environmental impact of the product and potential for obvious improvement in terms of environmental compatibility at a reasonable cost.

The classification into product groups is implemented by using the so-called Lots (Lot 1 for heat pumps, Lot 10 for domestic use air-conditioners up to 12 kW).

If the classes of minimum efficiency are not reached, a ban on the import into the European Union will be implemented.

This import ban is based on a very simple assumption: In the future, the energy label will be an integral part of CE conformity..

As a result, air-conditioning systems that do not comply with the minimum requirements will not be able to have the CE certification.

Sound pressure vs. Sound power

Sound pressure level dB(A)

The sound pressure level is a sound field parameter which indicates the perceived operating noise o fan internal unit within a certain distance.

Sound power level dB(A)

The sound power i san acoustic parameter which descrive the source strenght of a sound generator and is thus independent of the distance to the receiver location.Attention to efficiency and comfort

In the future, new classes of energy efficiency will be used.

In addition to an improved class of energy efficiency compared to that used to date, class A, the scale of values will be widened to encompass the classes A +, A ++ e A +++.

In addition, consumers will receive more important information relating to their purchase decisions such as information relating to noise emissions of the split air-conditioning system.

For this purpose, the level of sound power of the indoor unit and of the outdoor unit is indicated in decibels as objective acoustic parameter.

If the parameter relating to the sound power of an indoor unit is known, it is possible to calculate the sound emission, taking into consideration the distance and the characteristics of irradiation.

A very obvious advantage is the fact that it is possible to compare different air-conditioning systems regardless of the place of use and the method of measuring the sound pressure.

Often the sound pressure level is measured at a distance of approximately 1 m; at this distance modern split air-conditioning systems are very quiet and have an average value of 21 decibels.